Customization Sheet Metal Fabrication Strut Channel Strut Post for Electric Industries

Description

Basic Info.

| Model NO. | BHFS034 |

| Surface Processing | Zinc-Plated |

| Fine Blanking | Double Acting |

| Process | Bending |

| Industry | Metal Stamping Parts |

| Tolerances | 0.2mm |

| Customized | Customized |

| Industries Apply | Electric Appliance Furniture Agricultural Machi |

| Industries Application | Construction Machinery Parts Electronics |

| Industries Served | Automobile|Medical Device Industrial, Construct. |

| Inspection | in-House The Third Party |

| Software | Auto CAD, PRO/E, Solidworks, Ug (Dwg, Dxf, Igs, St |

| Industrial Use | Truck and Auto Parts |

| Service | Customized OEM |

| Related Products | Door Hinges|Door Fittings|Door Springsdoor Motors| |

| Manufacturer Process | Metal Cutting Bending Blanking Piercing Forming |

| Product Quality Certification | ISO9001:2015 |

| Apply | Hold 70j Eye Bolt |

| Application Place | Garage Door Parts |

| Size | Customerized |

| Transport Package | Carton Boxes and Pallets |

| Specification | Customerized |

| Trademark | Borhaf |

| Origin | Rizhao |

| HS Code | 73089000 |

| Production Capacity | 50000pieces/Month |

Product Description

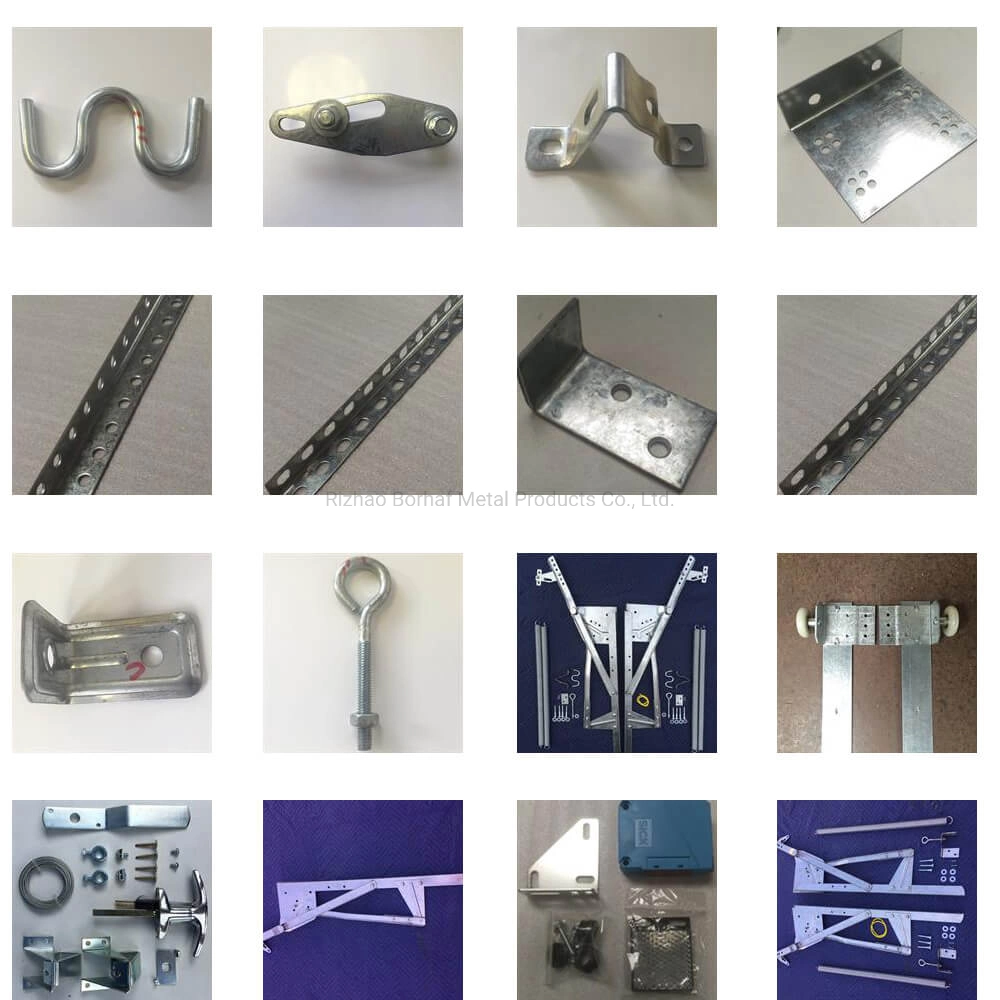

Main Products

About Borhaf Metal Fabricator:We specialize in all types of sheet metalworking / stamping, metal pressing and can manufacture custom pressed metal parts.Our main production and processing are all type of precision sheet metalworking/ stamping parts, custom-made precision metal stamping, welding assembly parts, Laser-cutting metal parts.Our precision sheet stamping parts includes Brackets, Cable anchor brackets,Frame, Vehicle Processing Parts, Automobile Spare Parts, Medical Device Parts, Industrial Machines, Electric Appliance Parts, Furniture Parts, Agricultural Machinery, Electronics, Construction, Machinery Parts and so on.Main products:Metal Stamping,Sheet Metalworking,Metal Brackets,Metal Fabricated,metal laser cutting,Mounting plate,Wood connectors,auto parts,Post Brackets,Adjustable Post Base,Sheet Bending,etc

ODM| OEM Case

The following is that we have developed a set of metal stamping products used in garage door series for customers. Please make a referrence.We have unparalleled competitiveness in the research and development of new products and the manufacture of samples. Please feel free to send us the drawings and our team will work closely with you.

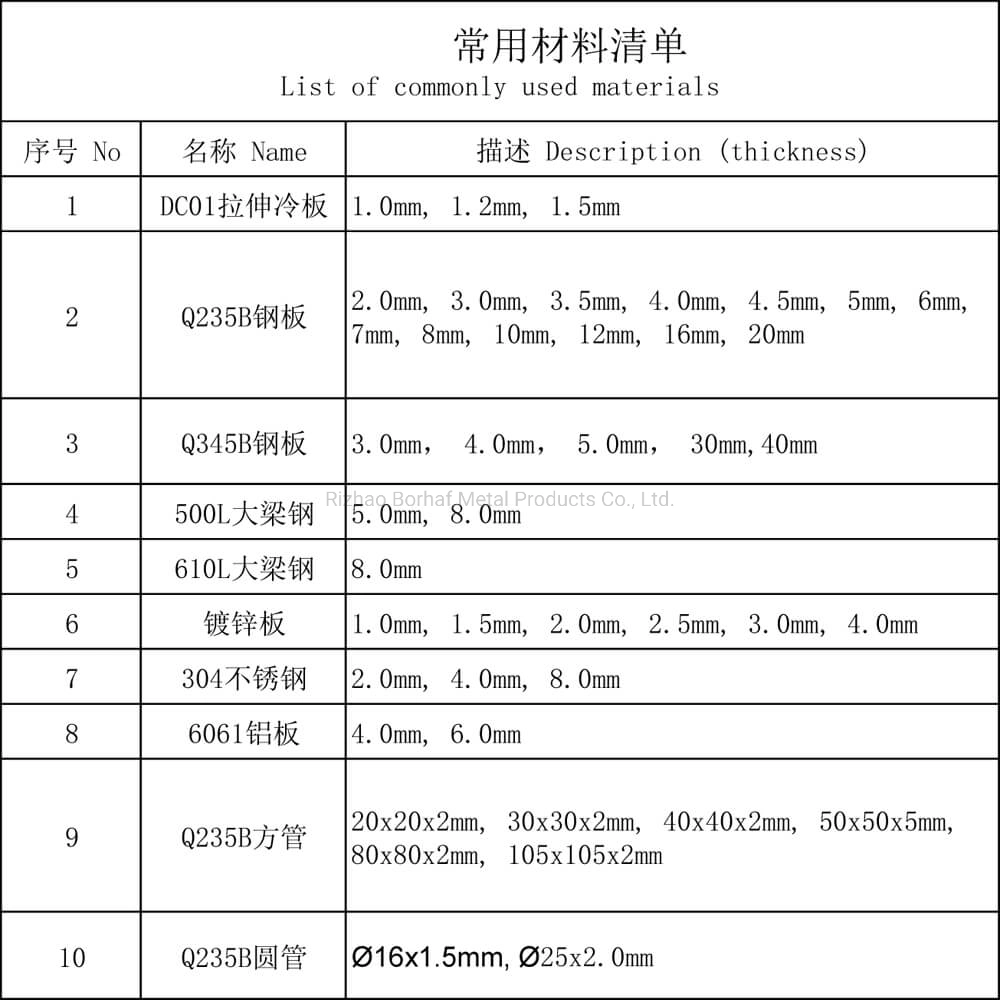

Product Description

| Material | Cold- rolled seels hot- rolled steels. galvanized sheets, copper, stainless steel, SPCC |

| SPE | Roll material thickness is 0.3- 10mm:; sheet metal thickness is 0.3-30mm |

| Prototype & Mould | In-house tooling design and manufacturing, |

| Specification | As your drawing or Sample |

| Processing | Metal Blankin Deep Drawing Sheet Bending Punching Pipe Bending Laser Cuttin Stamping Metal Weldin Piercig Formin Surface treatment |

| Surface Treatment | Poishing, gavanizing dacromet, chrome plating spraying black oxde coatin etrethoreris powder coating.etc |

| Tolerance | Stamping parts: 0.01-0.1mm CNC machining parts: 01-0.002mm or special requirements |

| Punching presss | 35Tons-250Tons |

| Maximum Press Bed Width | 2000mm |

| Maximum Press Bed Length | 1500mm |

| 250Ton CNC Press Brake Machine | Bending Material length 3200mm |

| 600W Laser ctting Machine | Laser cut Material thickness 30mm. |

| Maximum cttin thickness | Carbon sel:30mmstainlesss seel: 12mmAluminum and alys: 8mm. Tolerance:+ -0.05mm |

| Laser cutter work table | 2500mm X 600mm |

| 500Ton Oil Hydrulic Machine | Maximum Hycrulic presss stroke:. 1500mm |

| 2500 Plte ctting machine | Cut material thickness 16mm. |

| Welding Machine | Carbon dioxide welding. spot weldig. tig welding. automated robotic welding |

| Drawing Format | Auto CAD,Pro/E, Solidworks UG (dwg. dxf, IGS. STP. X-T). PDF. Pituresetc |

| Service Type | ODM | OEM |

| Certificate | 1S0900:2015 | SGS IBV TUV |

| Tech Stand | ISO. GB,JIS DIN,ASTM,ANSI |

| Application | automobile sareagricultural machinery, construction, electric apiaianefuiture hardware, home aplinces, Industrial machines, medical Device, machinery Parts. smal engine and so on |

Keywords:Metal Stamping,Sheet Metalworking,Metal Brackets,Metal Fabricated,metal laser cutting,Mounting plate,Wood connectors,Post Brackets,Adjustable Post Base,Sheet Bending,Sheet Metal Fabrication, Metal Fabrication, Sheet Metal Parts, Precision Sheet Metal fabrication, sheet metal, precision stamping, Precision Metal Stamping, Metal Stamping, Stamping Parts, Stamped Parts, Laser Cutting Parts, Laser Cut Parts, Custom Metal Stamping, metal parts, Metal Laser Cutting Parts, Laser Cutting, Laser Cut, Punching Parts, Punched Parts, Deep Drawn Part, deep drawing stamping parts, CNC machining parts, CNC machined parts, machining, turned parts, turning parts. Etc

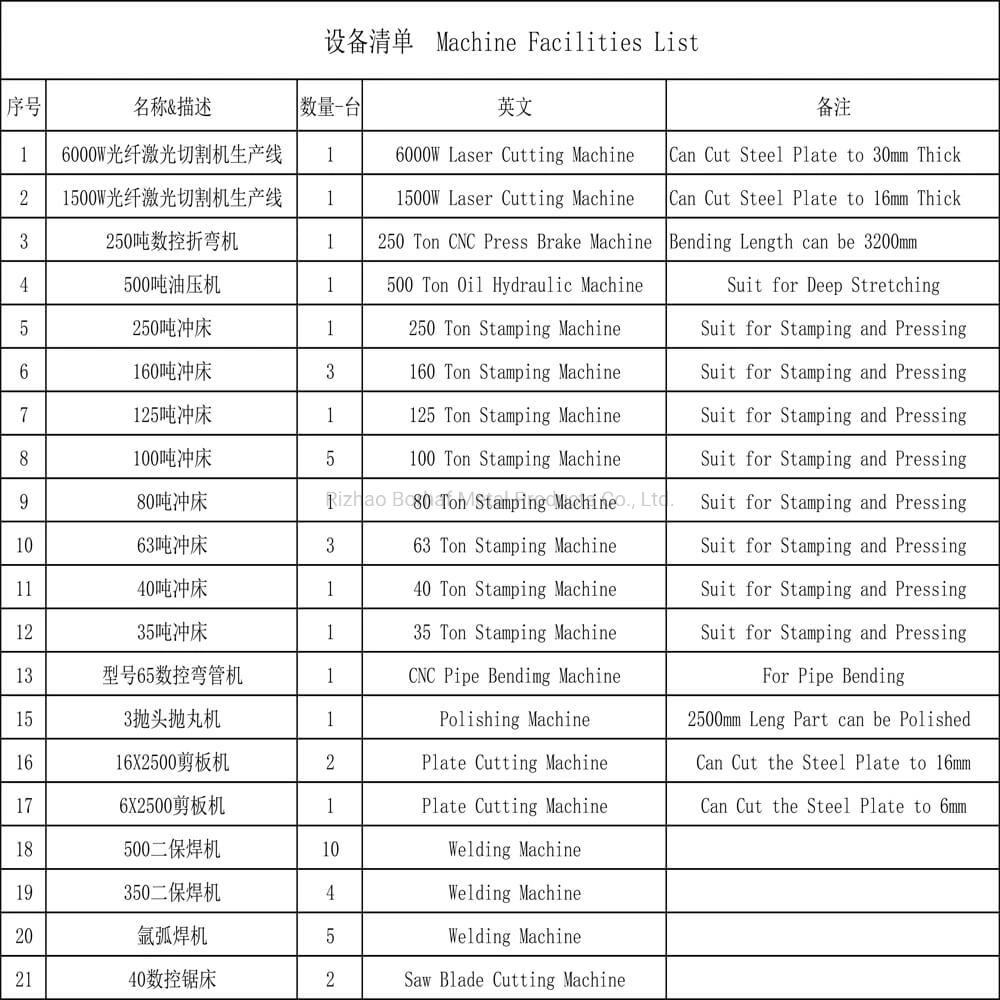

Workshop & Machine

Laser cutting Machine

Laser cutting is one of Borhaf metal fabricator sheet metal profiling processes that directs a high-power laser through optics to cut materials for industrial applications. Laser cutting is both more precise and less energy-consuming than plasma cutting, but has an upper threshold on the thickness of the material being cut. Borhaf's fiber optic lasers offers fiber can cut many materials including stainless steel,mild steel, copper, brass, titanium, aluminum. With a 2.5 meterX 6.0 meter work table, our laser cutter has ample room for large parts or for nesting multiple jobs on a single piece of sheet metal.

Measuring Tool

manufacturing process flow

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal is fed into a press, where the stamping tool, also known as a die, creates the desired shape. The die is pressed into or through the metal with tremendous force. The force used in the process is measured in tons.

Normally it is done with a cold-forming technique. the part can come out hot because of the friction that's created between the metal and the die from the force of the press.

At Borhaf, we perform a variety of custom metal stamping operations, including

Related Stamping Parts

Give you a better understanding of our product range, the following are a few commonly used sheet metal stamping parts for your reference, we can customize your needs, please send the drawings, we will serve you wholeheartedly.

FAQ :Q: What materials do you offer for metalworking and sheet metal parts?

A: We offer a wide range of materials, including steel, stainless steel, aluminum, and various metal alloys. Our team can recommend the best material for your specific application based on your requirements and industry standards

Q: Can you provide custom metalworking and sheet metal parts?

A: Yes, we specialize in custom metalworking and sheet metal parts. Our experienced design and engineering team can work with you to develop custom parts that meet your specific needs and requirements

Q: What quality control processes do you have in place to ensure the quality of your products?

A: We have a comprehensive quality control system in place, including rigorous inspection processes at various stages of production. Our facility adheres to ISO and other industry-specific certifications to ensure that our products meet the highest quality standards

Q: What is your typical lead time for producing metalworking and sheet metal parts?

A: Our lead times vary depending on factors such as the complexity of the project, material availability, and production capacity. We work closely with our clients to provide accurate lead times and strive to meet their delivery deadlines consistently

Q: Can you provide samples of your metalworking and sheet metal parts?

A: Yes, we can provide samples for your review and approval before proceeding with full-scale production. We believe that this is an essential step in ensuring that our products meet your expectations and requirements

Q: Do you offer design and engineering assistance for metalworking and sheet metal projects?

A: Yes, our experienced design and engineering team can provide support and guidance throughout the development process, from the initial concept to the final production. We can help with material selection, design optimization, and manufacturability considerations to ensure the success of your project

Q: How do you ensure competitive pricing for your metalworking and sheet metal parts?

A: We continually evaluate and optimize our production processes, material sourcing, and supply chain management to offer competitive pricing without compromising on quality or service

Q: What industries do you typically serve with your metalworking and sheet metal parts?

A: We serve a diverse range of industries, including automotive, construction, electronics, aerospace, defense, medical equipment, and more. Our team has the expertise and experience to meet the specific needs and requirements of various industries

Q: Do you have experience working with clients in the North American market?

A: Yes, we have extensive experience working with clients in the North American market. We understand the unique requirements and standards of this region and are committed to providing high-quality products and services to our North American customers

Q: What post-sales support do you offer for your metalworking and sheet metal parts?

A: We provide comprehensive post-sales support, including troubleshooting, technical assistance, and replacement parts if needed. Our goal is to ensure the ongoing success of your project and maintain a long-term partnership with our clients.

Our Contact